Seaweed Packaging Boxes: Innovations in Sustainable Packaging

The global demand for eco-friendly packaging solutions is skyrocketing as consumers and businesses alike recognize the urgent need to reduce plastic waste. One game-changing solution rapidly gaining attention is seaweed packaging boxes. Unlike traditional plastics, seaweed-based materials are biodegradable, renewable, and eco-conscious, making them perfect for industries like food, retail, and e-commerce. In this comprehensive guide, we’ll explore the concept of seaweed packaging, its benefits, and how companies are leveraging this innovation to make a positive environmental impact.

What Are Seaweed Packaging Boxes?

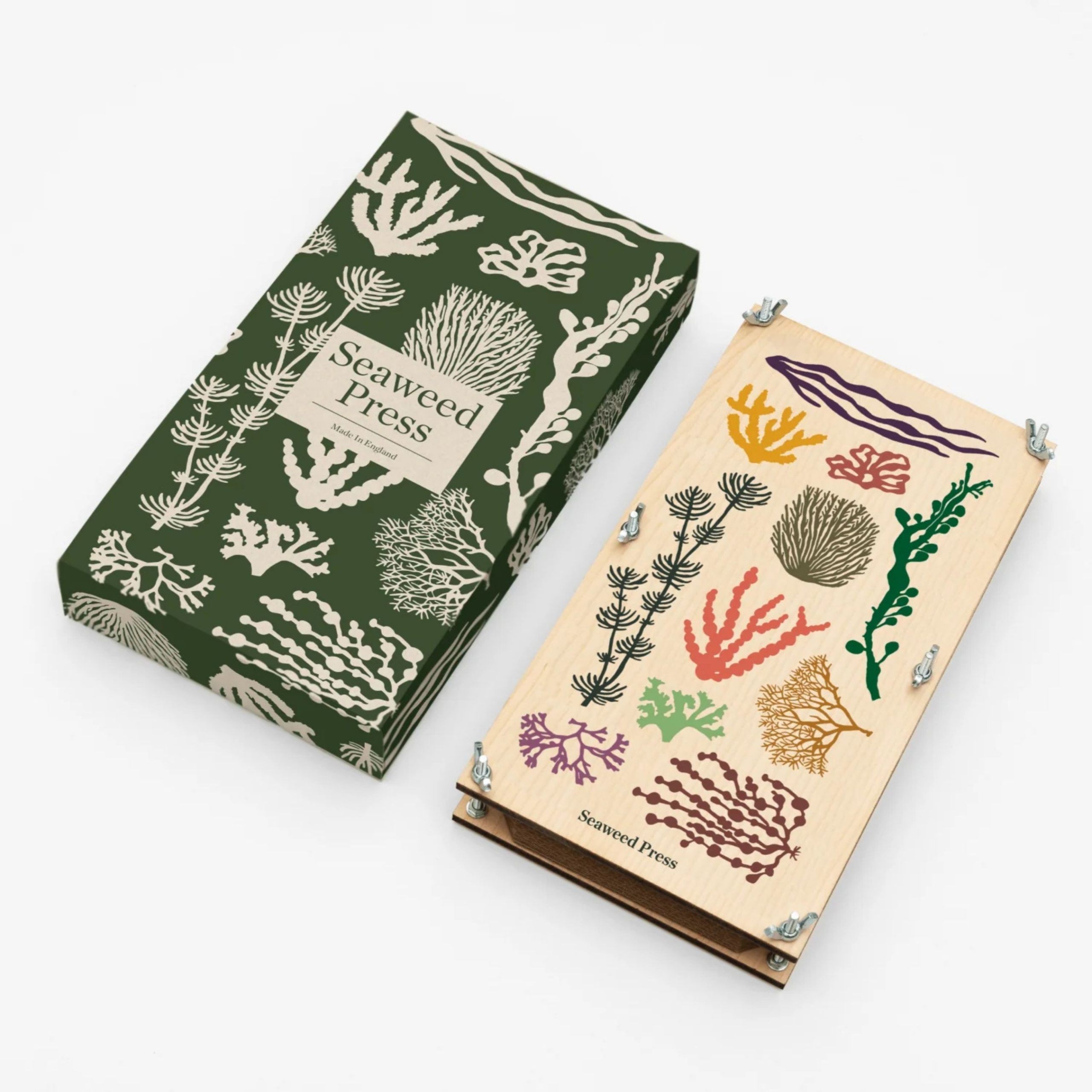

Seaweed packaging boxes are eco-friendly packaging solutions made from seaweed-derived materials. Seaweed, an abundant marine resource, serves as a sustainable raw material for creating packaging that is not only biodegradable but also compostable. These boxes are highly versatile and can be used in various industries, particularly in food packaging where reducing waste is critical.

One of the standout features of seaweed packaging is its ability to replace harmful single-use plastics. Leading innovators in this area, such as the pioneering Notpla seaweed packaging, have proven that seaweed offers functional strength, water resistance, and aesthetic appeal, all while being sustainable.

The Science Behind Seaweed Packaging

Seaweed packaging primarily involves extracting alginate, a natural polymer found in seaweed, and processing it to create durable, flexible, and lightweight packaging materials. Companies like Seaweed Plastic Company are investing heavily in research to explore the full potential of seaweed-based materials. Their goal is to create alternatives to petroleum-based plastics that are sleeker, stronger, and 100% biodegradable.

Seaweed packaging is also advantageous because growing seaweed does not require fresh water, fertilizers, or arable land, making it an eco-friendly resource that minimizes resource depletion and environmental impact. This makes seaweed-based solutions such as seaweed plastic bags and boxes highly attractive for environmentally conscious businesses.

Seaweed Packaging Boxes for Food: Why Are They Ideal?

One major application of seaweed packaging boxes is in the food industry. Due to their biodegradable properties, they are an excellent sustainable alternative for restaurants, delivery services, and supermarkets that aim to minimize their environmental footprint.

For example, Notpla seaweed packaging has been used as an alternative for takeaway boxes, offering water-resistant, grease-proof, and fully compostable solutions. Such products not only meet consumer demand for sustainability but also comply with increasingly stringent environmental regulations worldwide.

Working with manufacturers that specialize in creating Custom Seaweed Packaging Boxes ensures that your specific needs, such as design, size, and branding, are met while championing sustainability. Learn more about this innovation by exploring solutions that combine functionality with eco-consciousness.

How to Make Seaweed Packaging

Creating seaweed packaging involves a meticulous process that combines science and sustainability. Here’s an overview of how these eco-friendly materials are made:

- Seaweed harvesting: Seaweed is cultivated or collected from marine environments. Since seaweed is fast-growing and renewable, this step is highly sustainable.

- Polysaccharide extraction: Alginates and other polysaccharides are extracted from the seaweed. These natural polymers form the base material for seaweed-based packaging.

- Formulation: The extracted material is then processed and combined with other eco-conscious elements to meet specific strength, flexibility, or water-resistance requirements.

- Molding and drying: The final packaging material is molded into various formats, like boxes or bags, and dried to solidify its shape and strength.

Seaweed packaging manufacturers, including Notpla seaweed paper producers, are continually enhancing this process to offer cutting-edge solutions that meet the demands of modern packaging while prioritizing sustainability.

Benefits of Seaweed Packaging

The benefits of seaweed packaging extend beyond its environmental advantages. Here are the key reasons why companies are transitioning to seaweed packaging:

- Biodegradable and compostable: Seaweed packaging decomposes naturally, reducing waste accumulation and protecting ecosystems.

- Reduces plastic pollution: By replacing single-use plastics, seaweed packaging significantly alleviates the growing problem of plastic pollution.

- Renewable resource: Seaweed is one of the most sustainable raw materials, rapidly replenishing itself without excessive resource consumption.

- Functional and safe: Seaweed packaging meets industry standards for food safety, water resistance, and durability.

- Brand differentiation: Using seaweed packaging signals a commitment to sustainability, helping brands attract eco-conscious consumers.

Conclusion

Seaweed packaging boxes are a revolutionary step toward reducing our reliance on harmful plastics and creating a more sustainable future. As industries embrace eco-friendly alternatives, solutions such as small custom boxes made from seaweed are leading the charge in greener packaging initiatives. With innovations from companies like Notpla seaweed packaging and advancements in seaweed-derived materials such as seaweed plastic bags, the future of packaging is undoubtedly eco-conscious and resource-efficient.

Interested in integrating sustainable packaging solutions into your business? Explore the possibilities through expert manufacturers who specialize in custom seaweed packaging solutions to make a lasting impression while prioritizing environmental stewardship.